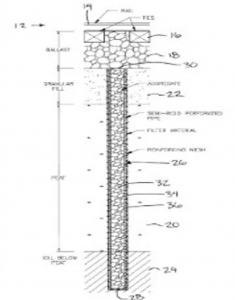

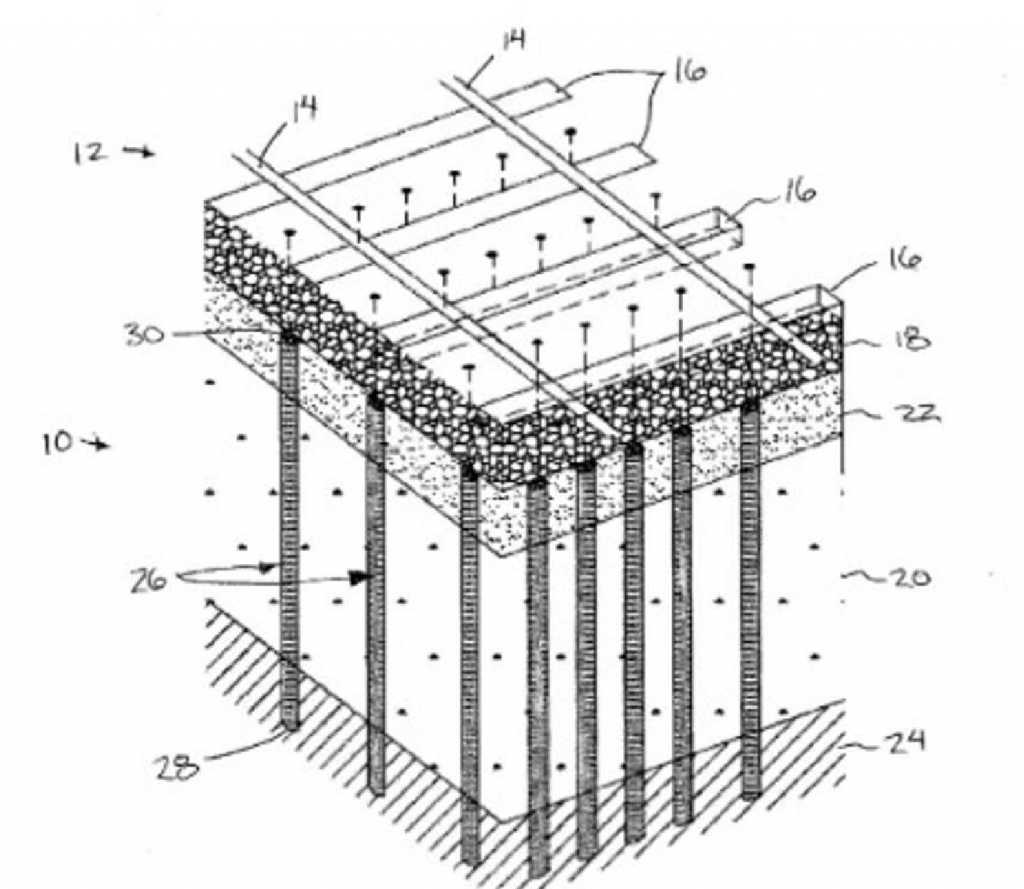

Spring Drains

A Patented innovation

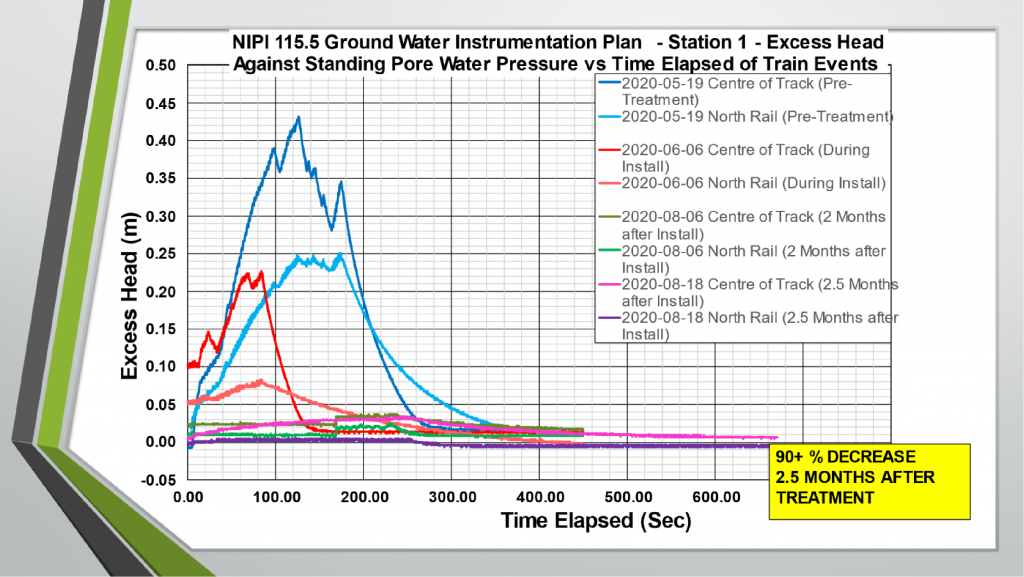

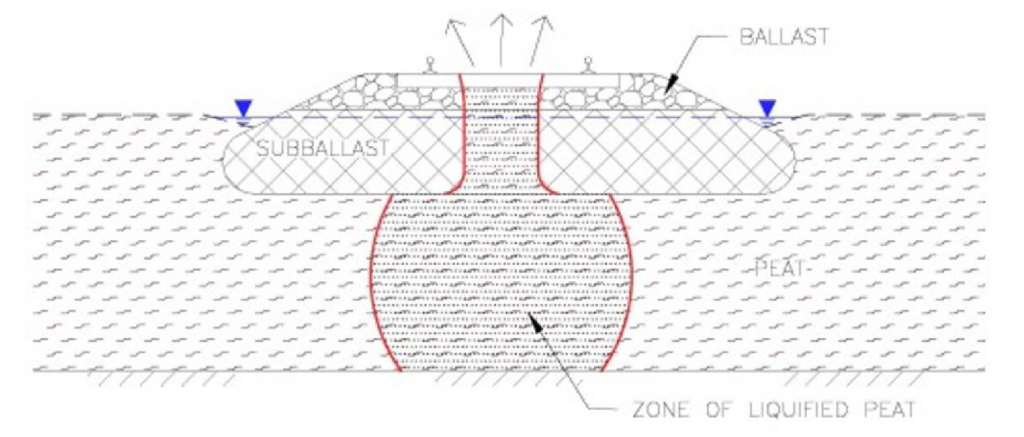

S Drains expedite porewater pressure dissipation while providing effective load transference into underlying competent soil strata. S Drains eliminated Peat Boils based on visual observations after one year. In partnership with Supercom Industries.